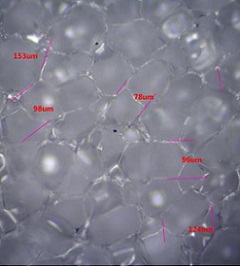

Expanded thermoplastic polyurethane (E-TPU) is thermoplastic polyurethane elastomer foam material which combines the properties of TPU with the advantages of foams, such as outstanding resilience and low density. Using an innovative procedure which putting TPU particles, foaming agents carbon dioxide and other additives into a sealed reaction kettle at a certain temperature and pressure through pressurization and decompression methods. The individual E-TPU beads have a size of from 5.5 to 7.0 mm and density of approximately 140-200kg/m³. Thanks to its closed-cell structure, E-TPU has excellent recovery behavior and excellent resilience which make it withstands prolonged and repeated compression without permanent deformation. E-TPU remains High elasticity and softness over a wide temperature range. E-TPU is environment-friendly material and also have non-yellowing grade.

|  |  |

| TPU | E-TPU | E-TPU under Microscope |

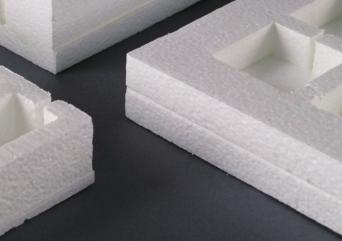

Owing to these properties, expanded thermoplastic polyurethanes are used in various applications, such as shoe industry (mid-sole, insole),sport and leisure sector (toy ball, rugby shell, plastic track, yoga mat),vehicle construction (transport plates,tire tubes, bicycle saddle, helmets, automotive trim). E-TPU can be used in where a combination of low weight, excellent mechanical properties and good long term durability is required.

|  |

|---|---|

| mid-sole | helmets |

bicycle tire | |

|  |

| packaging materials | plastic track |

E-TPU particles are pressed together under hot steam and bonded together. As gluing and foam sealing of the particles are possible, it enables large-scale processing.

Physical Properties of KOSLEN E-TPU shows as below

E-Physical Properties | |||

F-Item | G-Method | H-Unit | I-Result |

J-Hardness | K-ASTM D2240 | L-Shore C | M-30-50 |

N-Specific Gravity | O-ASTM D792 | P-- | Q-0.14-0.20 |

R-Abrasion | S-DIN 53516 | T-mm3 | U-50-60 |

V-Resilience | W-- | X-% | Y-≥61 |

Z-Compression Set | AA-ASTM D395 | AB-% | AC-≤18 |

AD-Tensile Strength | AE-ASTM D412 | AF-kgf/cm2 | AG-≥11 |

AH-Elongation At break | AI-ASTM D412 | AJ-% | AK-≥130 |

AL-Yellowing Resistance | AM-UVA*50℃*24h | AN-- | AO-≥4 |