Techniques for processing TPU: injection molding, extrusion, calendering and blow molding

TPU can be processed by a variety of techniques including injection molding, extrusion, blow molding and calendering.

Injection molding is by far the most important technique for processing TPU material. TPU are easily molded into shapes such as shoe sole, wheels, electronic parts, seals, toys, gaskets, orthotics as so on.

TPU are easily extruded into shapes such as tubing, wire & cable. Unlike injection molding, extrusion can be used to produce a very good surface finish. For best results, use extrusion grade TPU materials

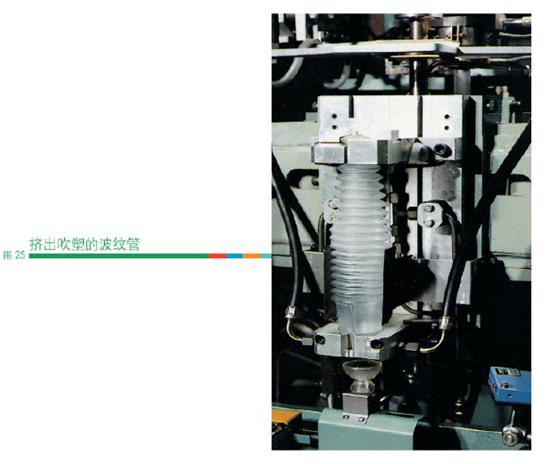

Another important process is extrusion blow molding in which air is blown into the mold to create the desired shape when molten plastic is extruded into a mold. Extrusion blow molding used to produce even complex hollow parts such as shoe cushion, car anti vibration part, bottles and containers.

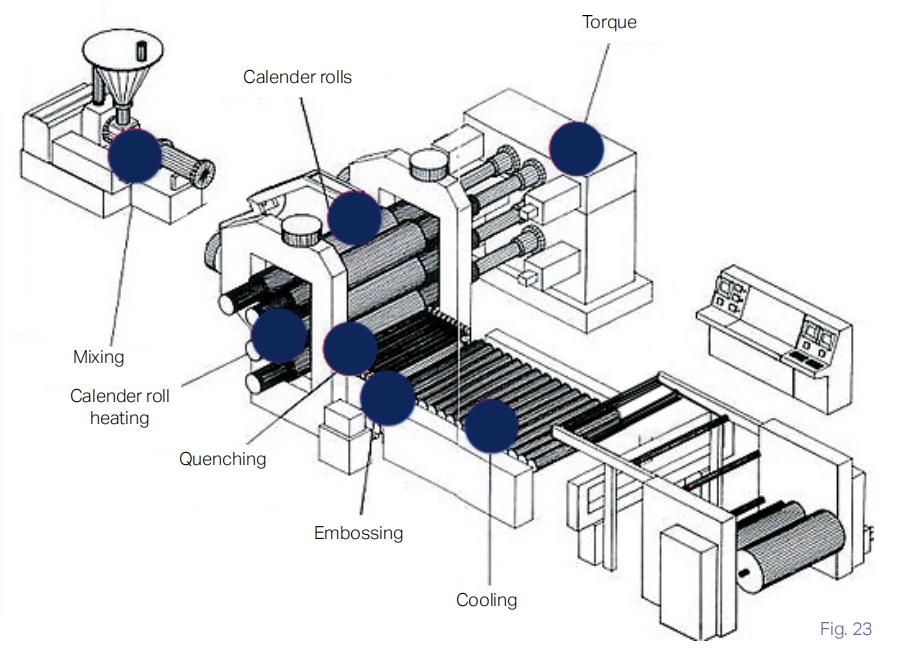

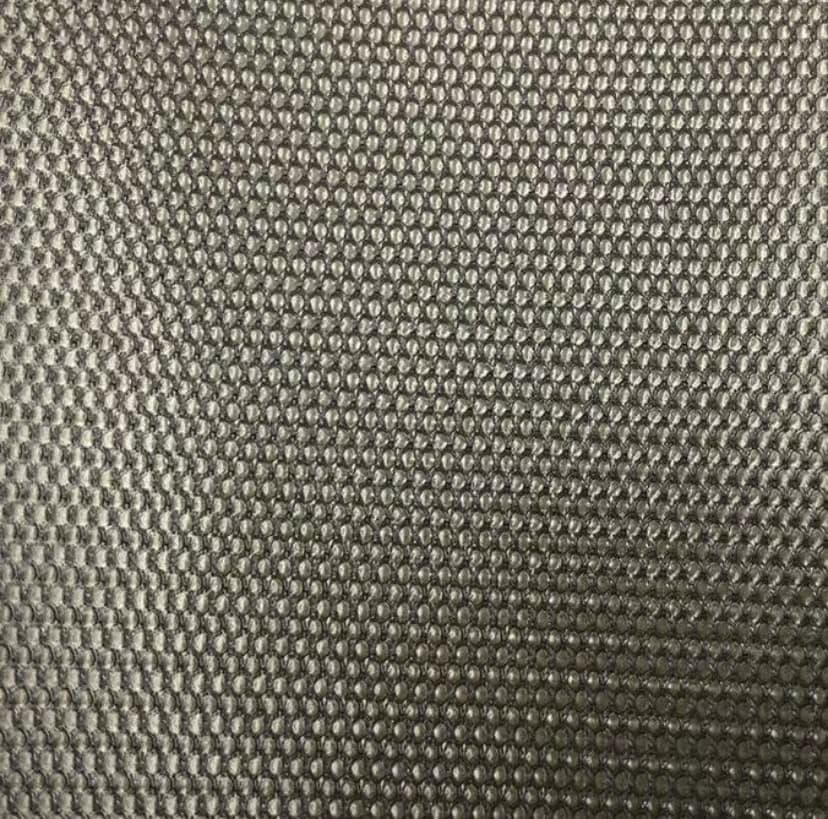

Calendering is a method often used for coatings applications. It is widely used as a means of coating Synthetic Leather and fabric. Calendering grade TPU features with no sticky on roller, low torque, workable for embossing, excellent adhesion and chemical resistance. TPU Calendering synthetic Leather is mainly for sofa seat, wall decoration, sports mat, luggage, car interior, and ship seat. Koslen grade B-785AL and S-670AL are widely used in Calendering process.

Thermoplastic polyurethanes (TPU) resin are durable, flexible and versatile plastic material. It is widely used in many industry