The molding cycle time refers to the total time it takes for a complete injection molding cycle, including the stages of filling, cooling, and ejection. The molding cycle time of TPU (Thermoplastic Polyurethane) can have an influence on the properties of the final injection products. A long molding cycle time for soft TPU (Thermoplastic Polyurethane) products can potentially cause various defects. Here are some common defects that can occur due to extended molding cycle times:

1.Overheating: Soft TPU materials are sensitive to heat, and an excessively long cycle time can lead to overheating. This can result in degradation of the TPU resin, leading to discoloration, reduced mechanical strength, or an increased risk of surface defects such as burning or scorching

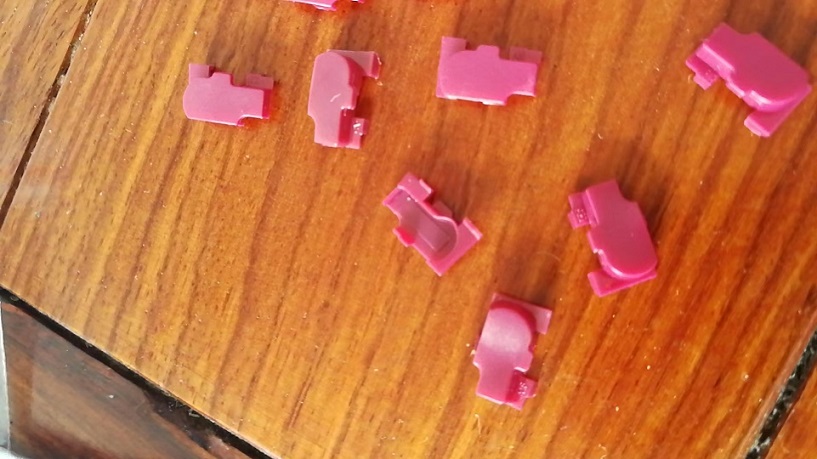

2.Warping or Deformation: Soft TPU materials have a higher tendency to deform or warp compared to rigid plastics. If the cooling time during the molding cycle is insufficient, the TPU product may not solidify and cool evenly, leading to warping or deformation. This can cause dimensional inaccuracies, uneven surfaces, or misshapen parts.

3.Sink Marks: Soft TPU products are susceptible to sink marks, which are depressions or dents on the surface of the molded part. These sink marks occur when the material cools and shrinks unevenly, creating localized areas of low surface pressure. Prolonged cooling times can exacerbate this issue, as slower cooling can lead to increased shrinkage and more pronounced sink marks.

4.Incomplete Filling: If the filling time during the molding cycle is extended beyond what is necessary, it can result in incomplete filling of the mold cavities. This can lead to short shots, voids, or insufficient material distribution, causing part defects and affecting the overall quality of the soft TPU product.

4.Incomplete Filling: If the filling time during the molding cycle is extended beyond what is necessary, it can result in incomplete filling of the mold cavities. This can lead to short shots, voids, or insufficient material distribution, causing part defects and affecting the overall quality of the soft TPU product.