The linear TPU natural plastic molecule contains many strong polar groups (such as ester group, ether group, carbamate group, urea group, biuret group and allophanate group, etc.), The strong forces between the molecules of these groups and the hydrogen bonds form physical cross-links.

TPU molecular structure determines that TPU plastic resin is easy to absorb moisture after be exposed in the air. TPU resin must be fully dehumidified and dried before processing into products (especially polyether TPU). High moisture content of TPU resin will lead to the following results:

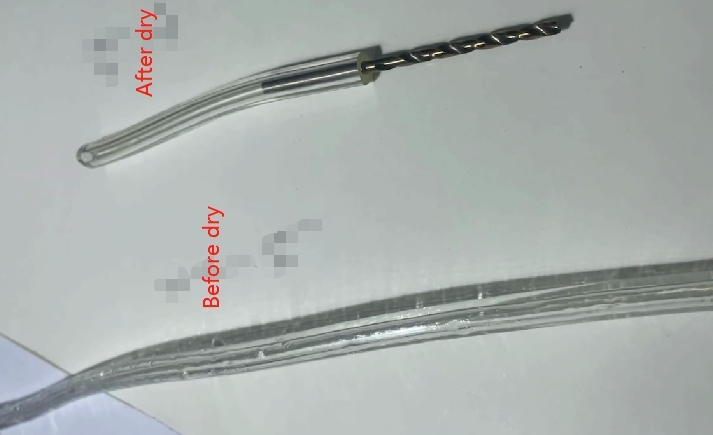

1. The high moisture content of polyurethane (TPU) will lead to difficulties in molding. For example blistering, flow lines, nozzle flow, fish eye, foam-like melts, bonding, poor product surface quality and poor physical properties;

2. The high moisture content of polyurethane (TPU) will lead to difficulties in extrusion. For example bubbles, waves, surges degradation.

TPU should be appropriate drying to ensured the moisture content is less than 0.05% (500ppm) before processing.

For THERMOPLASTIC POLYURETHANE TPU that Shore A hardness below 85A: at 80-90℃ drying 6 Hours

For THERMOPLASTIC POLYURETHANE TPU that Shore A hardness above 85A: at 100-110℃ drying 3-5 Hours

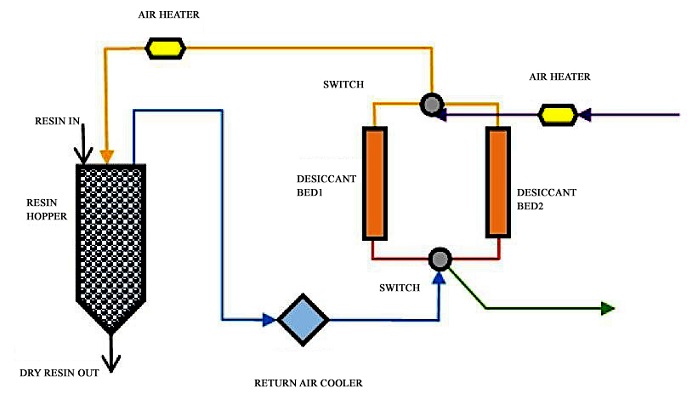

There are two types of drying systems, one is the drying bed system and the other is the drying wheel system. There is a closed loop circulation of heated "dry" air in the dehumidifying dryer to dry the resin. The moisture is released into the passing hot air.

The dew point meter in the dew point drying equipment provides an indication of drying air condition. The air will generate a low vapor pressure around the particles, which can attract moisture to the outside of the particles.