Warpage is the injection product defects that parts deviates from the shape accuracy requirements of the part. It is one of the common and difficult solved defects in injection mold design and injection production.

Causes of warpage

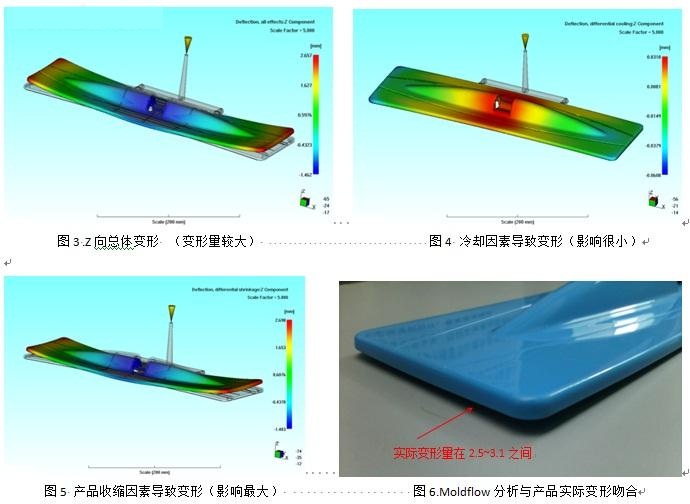

Warpage is caused by uneven stress and shrinkage during the products injection process. Die Adhesion, insufficient cooling, inadequate shape and strength of the part, poor mold design and process parameters, etc. can also led the plastic part warpage.

● The mold temperature is uneven, and the internal temperature of the plastic part is uneven.

● The difference in wall thickness and uneven cooling of plastic parts leads to the difference in shrinkage.

● The temperature is too high when the plastic parts are ejected or the ejection force is uneven.

● The shape of the plastic part is improper, with a curved or asymmetrical shape.

Improper position of the feed port and unreasonable injection process parameters make the shrinkage obvious different in direction and uneven shrinkage.

● The difference in the orientation of the molecular chain between the direction of flow and the Perpendicular to the direction of flow which results in different shrinkage rates.

● The wall thickness of the convex and concave molds is cooled asymmetrically, and the cooling time is insufficient, and the cooling is improper after demolding.

It take different measure to solve the warpage caused by different reason. The following table shows the treatment methods of warpage and deformation.

| Causes | Treatment method |

| The product has not been cooled when it is demolded | Extend the cooling time |

| Product shape and thickness are asymmetry | Change the molding design or add reinforcement ribs |

| Too much feeding | Reduce injection pressure, speed, time and feeding speed of raw material |

| Sprue feeding is uneven | Change the sprue or increase the number of sprue |

| The ejector system is unbalanced | Adjust the position of the ejector device |

| Uneven mold temperature | Adjust the mold temperature to balance |

| Excessive raw material buffering | Reduce raw material buffering |