Color difference is a common defect in TPU injection molded products. TPU injection products may be scrapped in batches due to chromatic aberration. There are many factors affecting chromatic aberration, involving raw material TPU resin, color masterbatch, the mixing of material and color masterbatch, injection molding process, injection molding machine, mold, etc. It’s difficult to control the color aberration in injection molding.

1. Control the color aberration of TPU raw material particles and color masterbatch

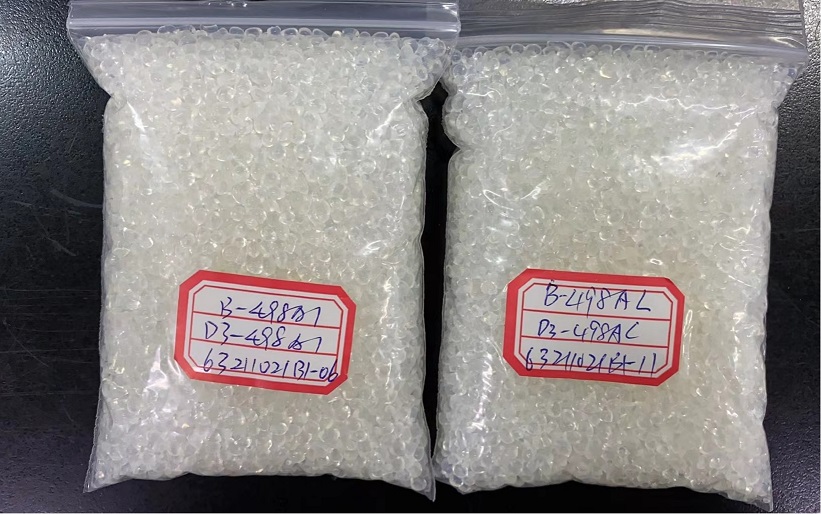

Different thermal stability of the material resin will lead to color fluctuation of the product, especially when producing light-colored products. Therefore, strengthen the inspection of incoming material. Color aberration of different batches incoming material must be control to within the scope. Factory must do test and manufacture sample with the color masterbatch before mass production. Color masterbatch can be qualified only if the color difference of color masterbatch is within the standard scope. Factory can mix the color masterbatch from the beginning to reduce the color difference caused by the uneven mixing of the color masterbatch itself. Plus, factory also need to check the thermal stability of the material resin and color masterbatch.

2. Eliminate the influence of injection molding machine and mold

chromatic aberrations caused by mold casting system, exhaust grooves, can be solved by repairing the corresponding part of the mold. Molding machine with an appropriate capacity can reduce the chromatic aberrations caused by dead corner of injection material

3. Control barrel temperature

Drastic changes of the barrel temperature can also lead to chromatic aberration. Generally, the chromatic aberration caused by the failure of the heating ring will be accompanied by uneven plasticization. The chromatic aberration caused by the out-of-control and long-burning of the heating control part is often accompanied by product air spots, severe discoloration and even coking. Therefore, it is necessary to check the heating part frequently during production and replace and repair it in time when the heating part is found to be damaged or out of control.

4. Color masterbatch fully mixed with masterbatch

The amount of color masterbatch will change by the effect of static electricity which cause color masterbatch separate from masterbatch and adsorbed on the hopper wall. Manual mixing after the plastic material sucked into the hopper will be necessary.