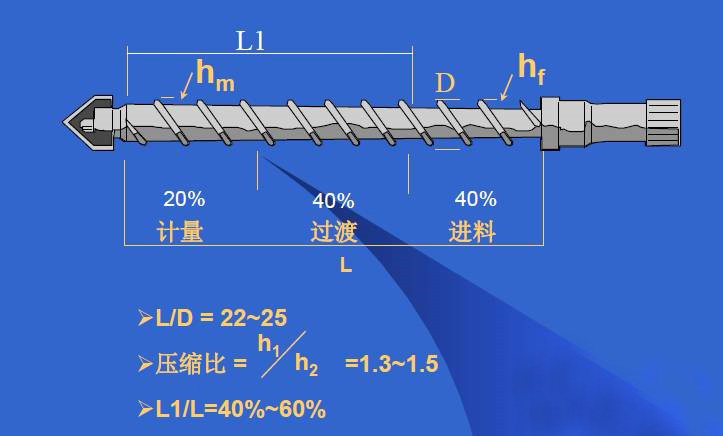

There are many reasons that cause the slippage of the screw barrel. For example, the abrasion of the screw and barrel. The compression ratio of the injection molding machine screw, if the feeding section is too short and the compression ratio is too small will led to the conveying capacity decrease and the screw slip. The one-way valve (check valve) malfunction can also lead the screw slip. In addition, the uniformity of the feed will be affect the processing uniform of raw materials, it may cause uniformly transport of the melt and lead to the screw slippage!

Analysis of the process parameters

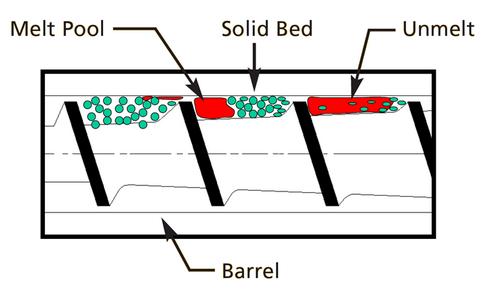

The low temperature in the back section of the barrel is usually the cause of the slip of the injection screw. The barrel of the injection molding machine is divided into three sections. At the back of the feeding section, a thin layer of molten polymer formed during the heating and compression process will help to transport forward the TPU granule. Without this thin layer, the pellets are difficult to transport forward. When the equipment and the charging barrel are too small , the residence time of the material in the barrel is too short to form this thin layer of molten polymer. The residence time of the material in the barrel is too short make the polymer to melt or mix insufficiently which will cause the screw to slip or stop.

Deal method

1.Add a small amount of plastic material in the end of the barrel to cleaning and check the melting temperature. The melting temperature will be lower than the set value of the barrel temperature if the residence time is short.

2.The marble markings, black spots or light streaks may appear in the injection products when the material is not well mixed in the barrel.

3.Sometimes the barrel temperature has to be raised above the recommended setting to reach in harmony in the screw rotation and retreat

Setting a too high backpressure can also cause the screw to stall or slip. Increasing the back pressure setting also increases the energy entering the material. If the back pressure is set too high will adversely affecting product quality and cycle time. The back pressure can be adjusted by the control valve on the injection barrel.

Analysis of equipment

If there are abrasion areas on the screw and barrel, the screw cannot effectively transport the material forward and screw slip of the injection molding machine caused. The screw and barrel should be inspected and the clearance between the two should be checked in this situation. Replacement or repair the parts if the fit clearance between the screw and barrel exceeds the standard value. If feeding section is too short will cause insufficient feeding which will lead the screw to slippage. As the shorter feeding section, the lower compression ratio, there will be different best compression ratio for different injection molding materials. The Malfunction of check ring (check valve) can also cause the screw to slip.

Data sheet of compression ratios for different plastic material

|

PLASTICTYPE |

FEEDING PARAGRAPH |

COMPRESSED PARAGRAPH |

ALL OF ABOVE |

|

Non-Crystalline Plastics crystalline plastics |

10%-25% full-length 60%-65% full-length |

55%-65%full-length 1-2 pitch |

22%-25% full-length 25%-35% full-length |

|

PLASTIC NAME |

COMPRESSION RATIO |

PLASTIC NAME |

COMPRESSION RATIO |

|

Hard PVC(tablets) |

2.5(2-3) |

PA-6 |

3.5 |

|

Hard PVC(powder) |

2-4(2-5) |

PA-66 |

3.7 |

|

Soft PVC(tablets) |

3.2-3.5(3-4) |

PA-11 |

2.8(2.6-4.7) |

|

Soft PVC(powder) |

3-5 |

PA-1010 |

3 |

|

PE |

3-4 |

FEP |

3.6 |

|

PP |

3.7-4(2.5-4) |

ABS |

1.8(1.6-2.5) |

|

PS |

2-2.5(2-4) |

POM |

4(2.8-4) |

|

PMMA |

3 |

PC |

2.5-3 |

|

MMS |

3 |

PPO |

2(2-3.5) |

|

MC |

1.7-2 |

PSU |

2-3 |

|

PET |

3.5-3.7 |

PH |

2.5-4 |

|

CPE |

2.5-3.3(2-4) |

TPU |

1.25 |

The improper shape and size of resin feed barrel which lead to unstable conveying of materials is also the cause of the slippage of many injection molding screws. Generally plastic pellets with uniform size can be processed well in a square feed barrel, but it will be easy to slippage when adding recycled materials in it. Try to use a circular barrel with a gentle gradient at the bottom for the recycled material and new plastic pellets processing.

Analysis of Material

The shape and size of the material particles will affect the continuity of the material feed. Uneven shaped pellet will be feeding difficult, injection factories can enhance the temperature in the back section of the barrel to make the material begins to melt more quickly. Plus, the high humidity of Plastic material is also easy to cause screw slippage. So, when process the Hygroscopic material nylon and TPU, the plastic material must be thorough dried.