1. The Pre-Processing of TPU granules

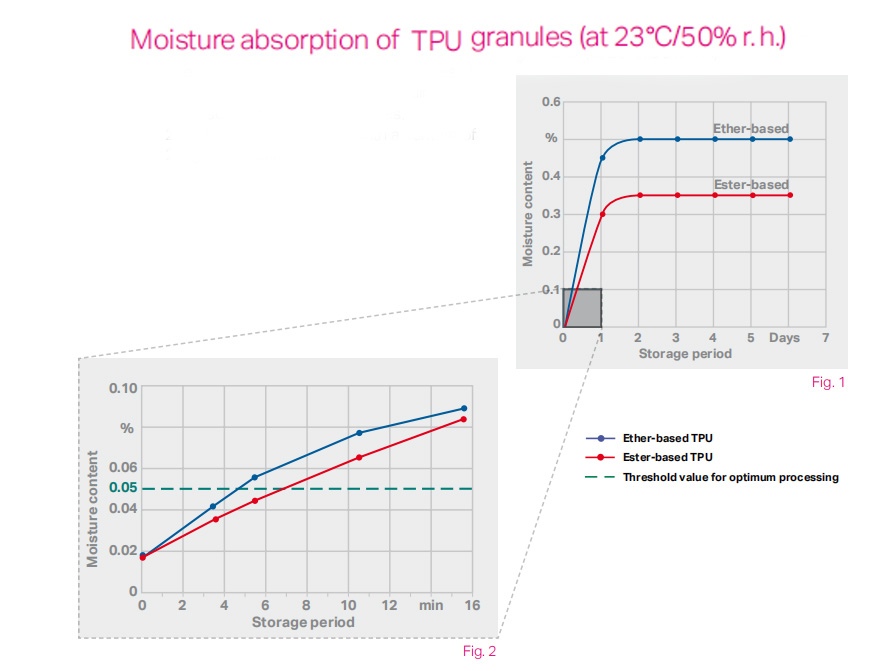

If the humidity of the TPU material is too high, it will cause small bubbles or silver streaks in the TPU products and the surface of the TPU extrusion products is unsmooth and brightness. We recommend that the humidity of the pellet material should be under 005% to ensure trouble-free surface molding products. The TPU granules will absorbed the moisture from the air. The moisture absorption speed influenced by the composition type, shape and environmental conditions. following figure showed the moisture content charged by storage period.

Usually, the undried functional masterbatch can also cause the above-mentioned product defects. These masterbatches must be dried separately and the moisture content is also controlled below 0.05%. According to the different hardness of the product, we recommend that the drying temperature be controlled at 80-110℃, and the drying time should be 1-3 hours. dehumidifying dryers can better drying the TPU granule in a shorter time.

Please note the dried TPU granule must be cooled in sealed container immediately after dry. It should be avoided to be exposed to the air when cooling.

2. Processing temperature of TPU extrusion process

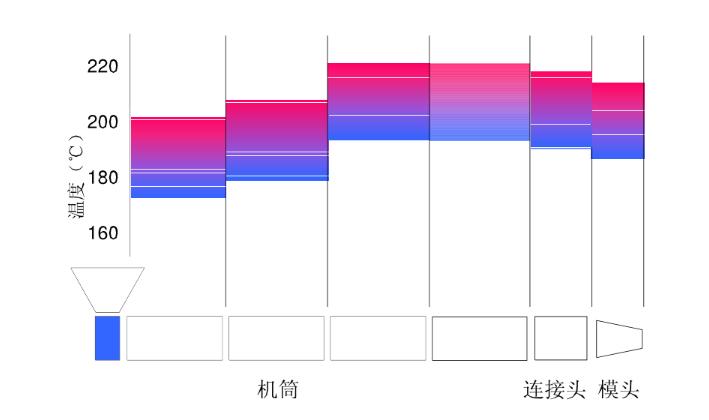

TPU melt viscosity are very high. To ensure that the TPU melt can be fully plasticized, and minimize the viscosity of the product surface at the same time, we recommend a low to high temperature distribution from the feeding section to the metering section, and a high to lower temperature from the metering section to the die. The temperature distribution diagram is as follows:

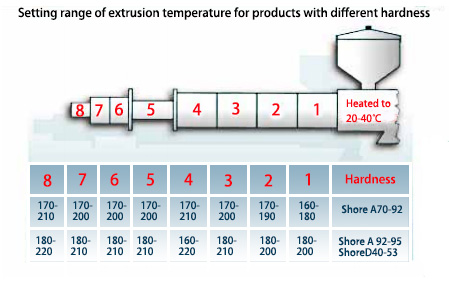

The setting temperature of TPU extrusion process is usually from 160°C to 230°C. the temperature setting must consider the factors of product type, TPU hardness and TPU melting range. The process temperature also affected by the the size of the extruder and screw. The circumferential speed of the screw should not exceed 0.3 m/s. As higher shearing force of larger extruder, it can set a lower temperature when use a large extruder. The low temperature of die head creates a dim, light plastic products surface. The high temperature of die head can make the surface smooth and bright. Below the temperature setting guidelines of the barrel and die heater for your reference.

3. Screw speed of TPU extrusion process

As TPU is very sensitive to shear force, so the screw speed should not be too high. However, if the screw speed is too low, the melt will stay in the barrel for too long to cause material degradation. Generally, the screw speed should be between 20-50RPM. The proper screw speed should be selected when the melt is completely plasticized, and the surface of the product is smooth and without bubbles.

4. The post-processing of the TPU extrusion tube products and TPU extrusion cushion products

TPU products can only reach their best physical performance level after being left at room temperature for a period of time. This process can be accelerated by annealing in a circulating air oven for 15 to 20 hours. For products with hardness ≤ 95A Shore, we recommend annealing at 80°C to 90°C, and for products with hardness ≥ Shore 93A, annealing at 100°C to 110°C. Only through annealing compression set rate can reach at the best