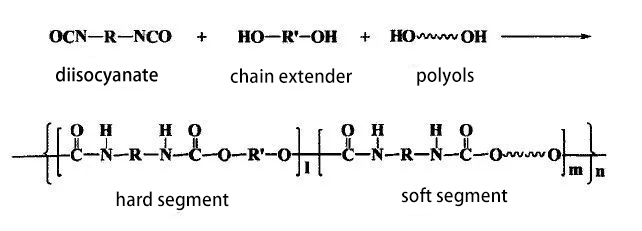

TPU is a block copolymer which is formed by the reaction and polymerization of diphenyl di-different properties (MDI), diisotropic compounds (TDI), macromolecular polyols and extender chains. It’s consisting of hard and hard segments. The soft segments are made of MDI, TDI and chain expander. The soft segments are made of MDI, TDI and macromolecular polyols.

The soft segments are macromolecule diol and can be classified as either polyester diol or polyether diol depending on the type of polyols. The molecular weight of soft segment ranges from 50 to 4000. With higher molecular weight of macromolecule diol, the elongation and elasticity of TPU is better. Concentration range of TPU soft segment is from 30% to 80%. The hardness, modulus and tear strength of TPU reduced when the concentration range of TPU soft segment increase. So physical properties of TPU can be adjusted by changing the concentration range of TPU soft segment. The concentration range of TPU hard segment determine mixability of hard segment and soft segment and also determine the degree of crystallization. In general, the higher concentration of TPU hard segment, the hardness , modulus and tear strength is better. Concentration range of TPU hard segment is from 20% to 70%. The soft segment and hard segment is connected by diisocyanate. The properties such as density, modulus, tensile strength, abrasion tend to be stable at 35,000-40,000 TPU molecular weight. The density of TPU is about 1.10 to 1.25. With the same hardness, the density of polyether is lower than polyester.

Oligomer | Crystallinity | Cold resistance | Hydrolysis resistance | Heat resistance | Oil resistance | Mechanical strength |

Polyoxypropylene glycol PPG | bad | excellent | excellent | general | general | general |

Polyoxyethylene glycol PEG | good | excellent | bad | good | general | good |

Polytetrahydrofurandiol PTMG | good | excellent | excellent | good | general | good |

Copolyether glycol EO/PO | bad | excellent | good | general | general | good |

Copolyether glycol THF/EO | bad | excellent | excellent | excellent | general | good |

Copolyether glycol THF/PO | bad | excellent | excellent | general | general | good |

Polyethylene Adipate Glycol PEA | good | general | general | excellent | excellent | excellent |

Polyethylene adipate PDEA | bad | general | bad | good | excellent | excellent |

Poly adipate-1,2-propylene | bad | general | general | excellent | excellent | excellent |

Poly-1,4-butanediol adipate PBA | excellent | excellent | good | excellent | excellent | good |

Poly-1,6-ethylene glycol adipate PHA | excellent | general | good | excellent | excellent | general |

Poly(neopentyl glycol adipate) PNA | bad | general | good | excellent | good | good |

A random copolyester P(E/DE) | general | general | bad | excellent | excellent | excellent |

A random copolyester P(E/P) | general | general | general | excellent | excellent | excellent |

A random copolyester P(E/B) | general | good | good | excellent | excellent | good |

A random copolyester P(H/N) | general | good | good | excellent | excellent | general |

Polycaprolactone PCL | good | good | good | excellent | excellent | excellent |

Polyhexylene carbonate PHC | excellent | general | excellent | excellent | excellent | excellent |

Polysiloxane polyol | bad | good | excellent | excellent | bad | bad |

Due to the types of monomers that make up the soft segment and the hard segment are diversity, it can be polycondensation different hardness, properties and usage TPU depend on the kinds of monomers. Classified by molecular structure, TPU can be divided into two types: polyester and polyether. Classified by processing method TPU can be divided to injection molding grade, extrusion grade, blow molding grade, etc. Classified by synthesis process TPU can be divided to Bulk polymerization and solution polymerization.

The Bulk polymerization can be divided into pre-polymerization method and one-step method depending on whether there is pre-reaction or not. The diisotropy react with the macromolecular diol for a certain period of time in the pre-polymerization method, and then add the chain extender to produce TPU; Macromolecular diol, diisoester and chain extender mixed and reacted at the same time in the one-step method. Solution polymerization is to dissolve the diisocyanate in a solvent first, then add a macromolecular diol to react for a certain period of time, and finally add a chain extender to synthesize TPU.