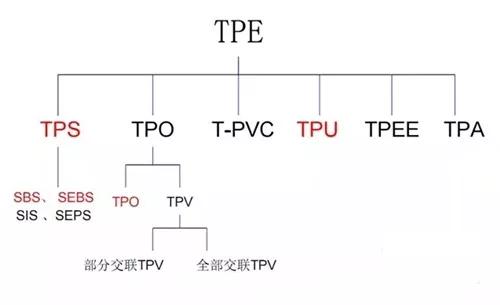

From the perspective of TPE is the general term for all thermoplastic elastomer, TPU is only one type of thermoplastic elastomer TPE.

In general, TPE refers to the alloy elastomer based on SBC (mainly SEBS, SBS) styrene elastomer blending modification, and it is also called TPES in some countries. Here we mainly discuss the difference in characteristics and applications of TPE and TPU.

TPE and TPU is with similar appearance and performance. They both have a certain degree of softness and rubber elasticity, and both can be used to produce shoe materials, smart speakers, smart bracelets, mobile phone cases, etc. The following i compare their form molecular structure, synthesis method, hardness control method, physical property difference, distinguishing method, application field sides

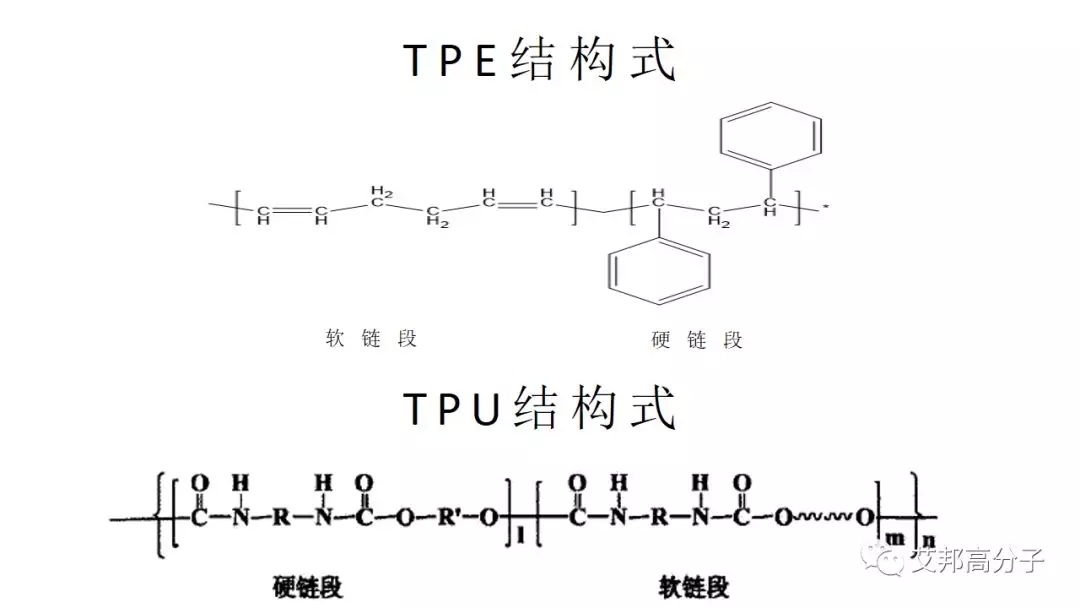

Molecular Structure

TPE is a styrenic thermoplastic elastomer which is a copolymer of butadiene or isoprene and styrene block polymerization. TPU is a polyurethane thermoplastic elastomer which is a block copolymer of diisocyanate molecules, polyols, and chain extenders reaction and polymerization

They are all block copolymers, but the composition of their soft and hard segment is different. The hard segment of TPE is polystyrene, and the soft segment is butadiene or hydrogenated butadiene. The hard segment of TPU is made of diisocyanate and chain extender, and the soft segment is a long chain of oligomer polyol.

Synthetic Method

The synthesis of TPE is generally synthesized by first reacting an equal parts of styrene, then adding butadiene to react, and finally adding a second equal parts of styrene for anionic sequential polymerization. TPU is generally synthesized by bulk melt polycondensation or solution polycondensation of diisocyanate and polyol.

In terms of the polymerization mechanism, the synthesis of TPE belongs to the anionic polymerization mechanism, and the TPU belongs to the polycondensation polymerization mechanism.

Hardness Control

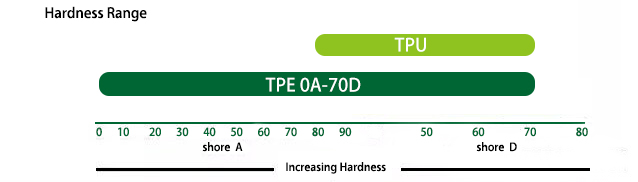

Both TPE and TPU can adjust the hardness, and both have a certain hardness range. The hardness of TPE is ranged from 0A to 100A, while the hardness of TPU is usually between 60A and 70D.

In addition to adjusting the styrene content to control the hardness, TPE can also control hardness through the degree of synthesis of vinyl, as the less vinyl is softer, the more vinyl the harder. TPE can be as soft as a PE plastic bag.

In generally, TPE is mixed with a variety of materials in products production, such as shoe material TPE is composed of 30% TPE, 30% oil, 15% polystyrene, 25% talcum powder or Calcium carbonate.

Hardness of TPU is mainly adjusted by adjusting the ratio of diisocyanate and polyol. It is usually used alone in products production or with a small amount of additives.

Differences in Physical Properties

①Hardness range: The Shore hardness range of TPE is 0A-95A, the hardness range of TPU material is 35A-90A (35-75A material cost is high), 50D-80D

②Material texture: Molecular structure of TPE is soft, it making TPE material with delicate and soft texture feel, and the surface of the product is smooth and comfortable; TPU is characterized by strong friction and without smoothness texture.

③Abrasion resistance: TPU is with greater abrasion resistance than TPE.

④Resilience performance: The resilience performance of TPU is better than that of TPE. The resilience performance of TPE becomes worse as the hardness increases.

⑤Oil resistance: .TPU material with great oil resistance while TPE material is not oil resistant.

⑥Mechanical properties: The load-bearing capacity, bending resistance, and tensile resistance of TPU is better than TPE. Therefore, TPU is more suit for heavy industry than TPE.

⑦ Specific gravity: TPE material has a specific gravity of 0.8-1.3, and TPU material has a specific gravity of 1-1.4.

Differentiation Method

The performance of TPE and TPU is quite similar, and it is impossible to distinguish it by the naked eye. it can be distinguished by some simple methods.

① Pinch with your hands

Pinch by hand, mainly to see the elastic recovery ability. The elastic recovery of TPE is relatively slow, while the elastic recovery of TPU is relatively fast. Product made of High-hardness TPE is prone to deformation. In all hardness ranges of TPU shows excellent elasticity, and the product is not easy to deform.

②Touch it with your hand

In terms of texture, TPE feels a little more soft while TPU feels a little rougher. TPE is more excellent in terms of comfort to the touch. TPU is more excellent in elasticity and strength.

③Burn it with fire

When TPE burns, the flame of it is yellow and blue, and there are slight bubbles at the bottom of the flame. The smell is special aromatic with the smell of petroleum (the smell of petroleum is the burning smell of PP components). When the TPU is burning, the flame is basically yellow, and the bottom of the flame foams strongly, there is a slight explosion sound, and a pungent odor.

④Look carefully

For transparent products, the transparency of TPU is better than that of TPE, and it is not as easy to stick as transparent TPE.

Application Field

Both TPU and TPE can be applied to produce wire and cable, pipe, shoe material. In generally, there are some general principles for choosing TPE or TPU. For example, TPE is more suitable in the products that the hardness requirement is low; If abrasion resistance and elasticity are required, then TPU is more suitable.

Application areas of TPU

1. Automobile industry

Because TPU has good mechanical properties, it is resistant to oil, grease, high and low temperature, elasticity and wear resistance. It is widely used in the automotive industry. For example, brake pipes, oil pipes, emergency airbags, interior trim parts, etc.

2. Cable

TPU features with the characteristics of excellent tear resistance, abrasion resistance, bending resistance, high and low temperature resistance, resistant to chemicals, hydrolysis and microbial decomposition which is the key to cable performance. Therefore, high-grade cables such as control cables and power cables use TPU to protect the covering materials of complex cables.

3. Pipe

TPU is flexibility, resistance to cracking, not easy to twist, and good elastic recovery in a wide temperature range. The characteristics of welding, oil resistance, chemical resistance, grease resistance, etc., make it the ideal material of high-end pipes. It can be made into oil pipes, water pipes, compressed air pipes, pneumatic components and air pressure pipes.

4. Shoes and sports equipment

TPU is with greater elasticity and better mechanical strength, better abrasion resistance, crack resistance, flexibility. It has become the material of a variety of special shoe soles and uppers with extremely high requirements. Such as football shoes, ice skate shoes, hiking shoes, work shoes, etc., It can be used as spherical materials for football, handball, basketball, volleyball and auxiliary materials for various sports equipment.

5. Profiled material

Since TPU materials can be processed into various shapes by plastic processing methods such as injection molding, extrusion, and calendering, it is the preferred material various for high-end decorative lines, sealing strips, and soft and hard decorative strips.

Application areas of TPE

TPE is not only has the ozone resistance, weather resistance and aging properties of PVC, but also improve tensile strength, tensile stress, tear resistance, heat resistance and flame resistance. It also has comprehensive properties such as oil resistance, fuel resistance, chemical resistance, and easy coloring. In addition, the main material PVC is abundant and with low price, so it is widely used in many fields.

1. Wire and cable

TPE can be applied to the electric cable industry, and it can compete with TPU and TPV in the application of special cables and submarine cables.

2. Hose

TPE can be used as a hose material, especially oil-resistant hose and gas hose.

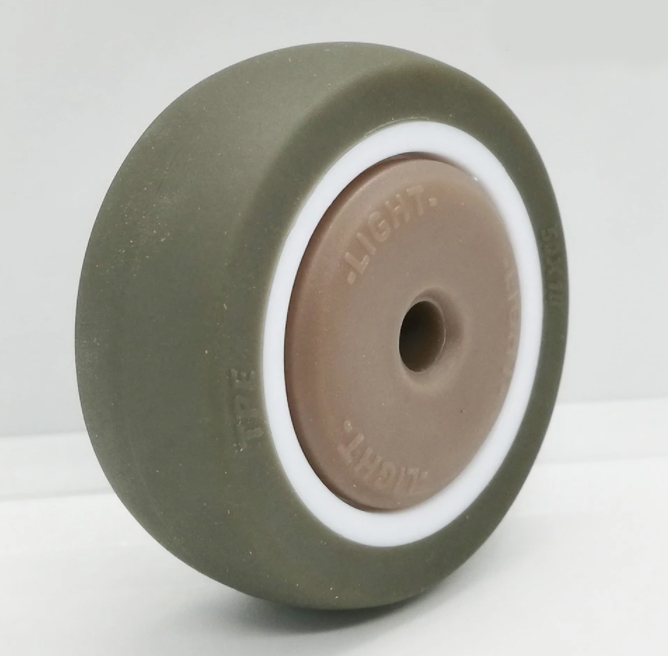

3. Rubber roller

The rubber roller is a metal core processed by a certain process and covered with rubber. For a long time, rubber rollers are mostly covered with rubber. TPE is used to replace rubber in the covered material of rubber rollers.It is widely used in the rubber rollers which required by latex glove production lines, printing, printing and dyeing, and textile industries.

4. Sole material

Like TPU, TPE is the latest generation of sole materials.It is not only with excellent performance in oil resistance, solvent resistance, flex crack resistance and abrasion resistance, but also cheaper than TPU and has become a shoe sole material with high cost performance.

5. Other

In addition, TPE can also be used in the production of foam plastics, protective coatings, flame-retardant conveyor belts, various special-shaped materials, soft and hard decorations and high-end decorative strips.