The types of plastics used in 3D printing plastics are becoming more abundant, and some products have achieved mass production. Plastic consumables account for 46.5% of 3D printing materials. PLA, ABS, nylon, and light-curing liquid resin consume relatively large amounts of the plastics consumables. In addition, thermoplastic elastomer (such as TPU) and engineering plastics ( For example, PA6, PC), special engineering plastics (PEEK, PPSU) and other polymer materials are gradually used in 3D printing industry.

As a common type of thermoplastic elastomer TPU features with flexibility, high mechanical strength, wide range of hardness, excellent chemical resistance and excellent weather resistance. It can processed by FDM (fused deposition), SLS (selective laser sintering) 3D prints process.

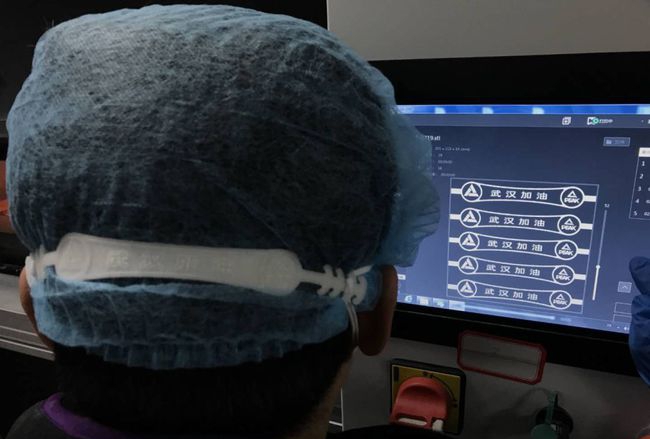

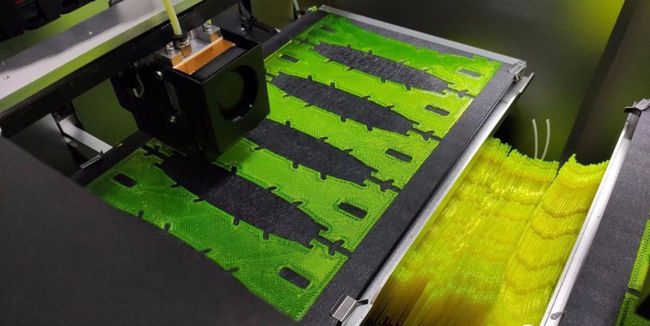

At present, 3D printing had been applied in mass production of shoe mid-soles, shoe uppers and also applied in elastic models, automobiles, and drones. In this new crown pneumonia epidemic, many medical staff and community workers have worn masks for a long time, and Ears and faces of medical staffs have been strangled red and even skin injury caused by a long time masks worn . The 3D printed mask adjustment buckle became a popular application to solve the pain points of wearing masks during the pneumonia epidemic. In order to obtain a good wearing experience, the material used for the mask adjustment buckle needs to have a certain degree of flexibility and wear resistance. TPU material (thermoplastic polyurethane elastomer) not only has good properties such as elasticity, softness and wear resistance, but also can be recycled, so it is recommended by material companies and favored by 3D prints manufacturers.

KUNSUN TPU 95A material S-695AL has high elasticity, excellent abrasion resistance and weather resistance, low shrinkage rate and good stability. It is also features with good flexible and abrasion resistant, which basically meets the strength and bending requirements of the mask during wearing. TPU mask adjustment buckle can easily fit the surface of the head without causing strangulation. It can still achieve a good wrapping effect even when the user wears a hat. TPU material is biodegradable, safe and environmentally friendly, skin-friendly, breathable, and harmless to the human body.

3D printing consumables TPU (Thermoplastic Urethane) is a mature environmentally friendly material between rubber and plastic. Below characteristics make it be an better material for 3D printing than other plastic materials.

1. Strong toughness: TPU's modulus of elasticity is usually 10~1000Mpa, and its products have good flexibility and resilience. TPU products and can be bent repeatedly without deformation.

2. High mechanical strength: TPU products have outstanding bearing capacity, impact resistance and shock absorption performance. .

3. Wide range of hardness: TPU hardness ranged from Shore A 65 to Shore D 75.

Please note the lower the hardness, the higher requirements for the 3D printer.

4. Wide operation temperature range of TPU products: TPU resin is flexible in a wide temperature range of -40~120℃, and does not need plasticizers.

5. Oil resistance and weather resistance: TPU material has good resistance to oils (mineral oil, animal and vegetable oils and lubricants) and solvents. In addition, TPU resin has good weather resistance and excellent resistance to high-energy rays.

Precautions of TPU 3D printing process

1. Model limitations: Thermoplastic polyurethane are not suitable for 3D printing which the printing models are too high as the top of models is easy to swing;

2. Fan control: Do not use a fan to directly blow the model to dissipate heat during printing;