The shrinkage of plastics is the volume contraction ratio of polymers from melt state to the cooled and rigid state. Most of the shrinkage occurs in the mold while cooling. A small amount of shrinkage occurs after injection as the molded part continues to cool. Total shrinkage is a result of molding shrinkage and post-shrinkage.

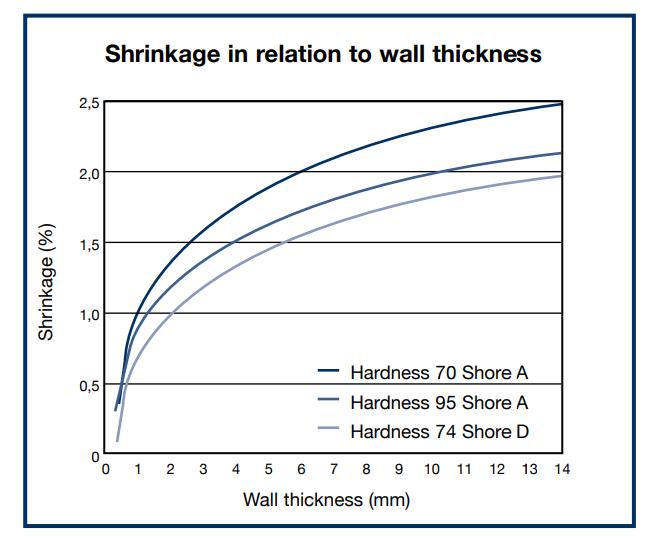

The shrinkage of TPU plastic resin is ranged from 0.1% to 1%. The shrinkage of TPU moldings is influenced by a number of parameters including part design, wall thickness, gate design and processing conditions, Melt and mold temperature as well as injection and holding pressure. The thicker wall thickness the higher shrinkage of TPU, the lower shore hardness the higher shrinkage of TPU. Please reference below Figure about shrinkage for TPU grades in relation to wall thickness and Shore hardness.

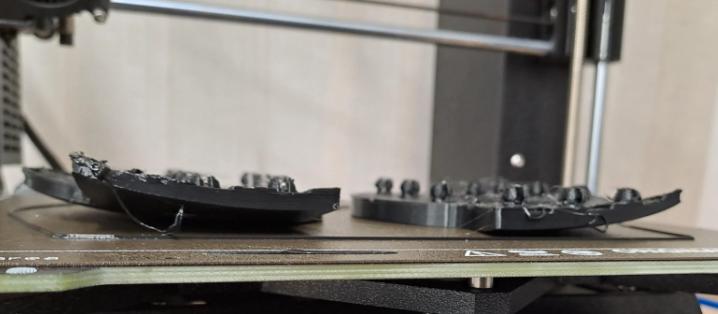

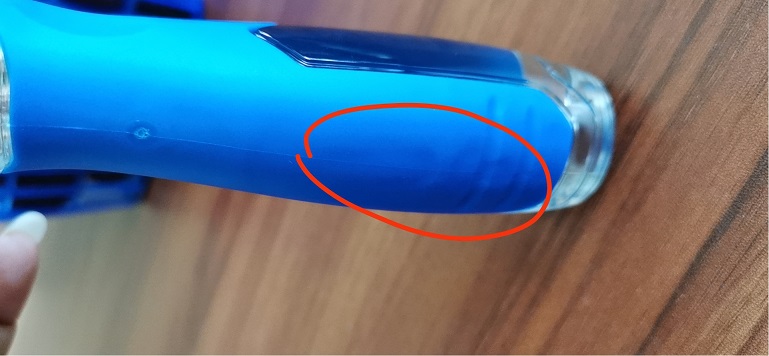

This volume contraction caused by shrinkage of polymers often leads to wrapped parts and dimension differences. For the parts required stablized dimension and seamless assembled products, the amount of shrinkage needs to be accurately predicted.

For the product defect caused by shrinkage, please try to solve by below tips:

Increase injection pressure

Increase pack-hold time or cooling time

Lower TPU melt temperature

Lower TPU mold temperature

Lower holding pressure