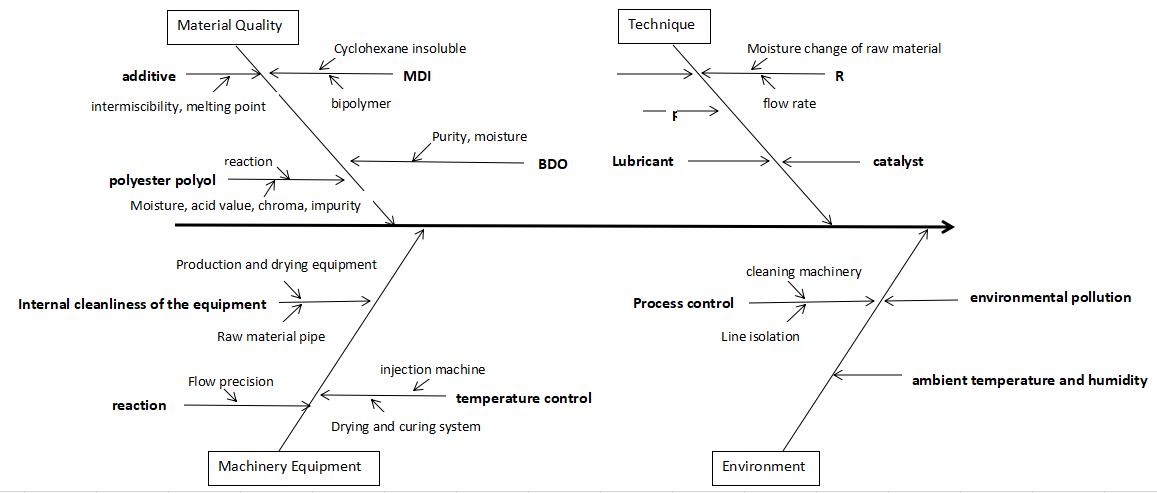

TPU film is formed by extrusion processing of TPU particles, mainly including blow molding, casting, calendering and extrusion coating. blown TPU film can be used for shoe materials, waterproof and transparent clothing fabrics, medical and defense supplies, weapon packaging, tents, sports and leisure equipment, sanitary napkins, toys, and civilian daily necessities packaging. It is the most widely used procession of TPU film. Cast TPU film can be used in shoe materials, waterproof and moisture-permeable clothing fabrics, weapon packaging, tents, sportswear, daily necessities, etc.; calendering is mainly used in the production of TPU sheet products, TPU sheet is used in the production of transparent shoulder straps, medical packaging materials, Safety bulletproof glass laminated film, conveyor belts, interior materials, liners and other products; Extrusion coating is generally used to produce composite fabrics. TPU is coated with non-woven fabrics, industrial fabrics, and apparel fabrics at one time to form the composite fabrics, which can be used for apparel fabrics, Trademarks, gloves, etc. The most common quality defect of thermoplastic polyurethane elastomer TPU film is fish eye. The following figure analyzes the influence factor of quality of raw materials, process methods, and equipment.

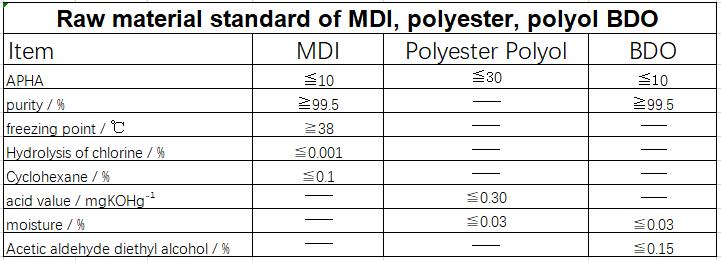

Quality of raw material of TPU

TPU is generally formed by the reaction of polyester or polyether polyol, diisocyanate and small molecule glycol chain extender. When synthesizing TPU from polyester diol or polyether diol, diphenylmethane-4,4'-diisocyanate (MDI) and chain extender 1,4-butanediol (BDO), it may occur side reactions of cross-linking bonds such as urea, allophanate and biuret at a certain temperature and trace amount In the presence of moisture or trace metal impurities or other impurities.

Therefore, it must strictly control the quality of raw material of TPU to reduce the fish eye in TPU film. The following table shows some raw material standards of TPU production for your reference.

Meanwhile, the influence of additives must be also take into account. It needs to consider compatibility or melting point with polyester or polyether polyol, when additive added to polyester or polyether polyol. It is required that the additives will not be decomposed and carbonized to form impurity in the TPU processing temperature which is as high as 200 ~ 220 ℃. That’s why high temperature resistance and decomposition temperature must be considered for all additives..

Procession

process control is particularly important for product stability and fish eye control. Process control is mainly includes the stability of the raw material flow, the melt index (MI value) on-site detection and control, and the reaction activity of the raw materials. TPU manufacturing processing include cleaning the equipment, adjustment of processing temperature and screw speed, filter mesh number, lubrication effect and other control points. Some additional lubricants are needed to be add to improve the surface effect and fluidity. The main influencing factors and solutions such as the isocyanate index (R value) and MI value during production and processing are shown in the table below.

|

Control Item |

Influence Factor |

Solution |

|

R |

1. moisture content of raw material |

Control the moisture content of raw materials within 0.03% |

|

2. Fluctuation of perfusion flow |

Set the flow fluctuation range within 0.02% |

|

|

MI |

change of R value |

Control the moisture content of raw materials within 0.03% |

|

Set the flow fluctuation range within 0.02% |

||

|

reaction |

1. Catalyst type |

Choose catalysts that are not easily hydrolyzed |

|

2. Catalyst addition method |

Side add catalyst to prevent catalyst hydrolysis in polyester or polyether polyols |

|

|

lubricant |

Type and amount of lubricant |

Choose appropriate internal and external lubricant and add amount to reduce residue |

|

process |

Percolator |

Increase Filter mesh |

|

Lubricant |

External lubrication to prevents the melt from sticking to the inside of the screw or the |

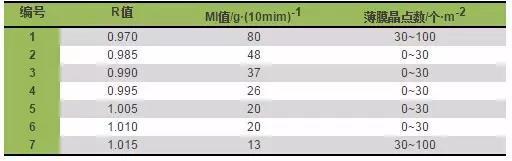

TPU with different R values (or different MI values) mixed processing will affect the fish eye of TPU film products.The following table shows the influence of different R values and MI on the fish eye of the film.

If the R value or MI value is too low or too high, the amount of fish eye per unit area is relatively large. This is because the difference in the degree of polymerization leads to a wide distribution of relative molecular mass. Difference relative molecular mass with difference melting temperature and lead to fish eye as TPU with high relative molecular mass is not easy to melt. Therefore, the R value of TPU is generally selected between 0.985 and 1.010 for transparent film production. In addition, the difference flow rate of the three-component will directly lead to the difference in the R value and the MI value. It is important to control the three-component flow rate. Experiments have shown that the difference of MI value ≥ 10, and the mixing of products with R<1 and R>1 may cause fish eye.