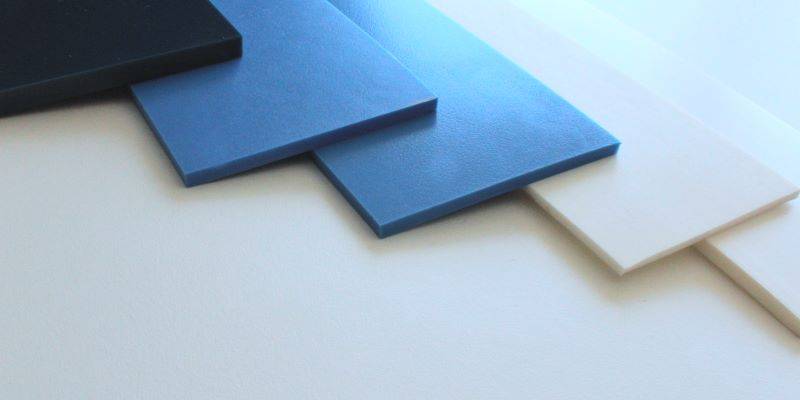

Thermoplastic polyurethane (TPU) bridging the gap between rubber and plastics, this elastomer is particularly versatile. Its toughness and safer for health and our environment properties make it a well adapted material for the the coating of conveyor belts.

Thermoplastic polyurethane (TPU) is widely used in coating conveyor belts as it offers:

TPU conveyor belts can be processed by extrusion calender coating and coated process.

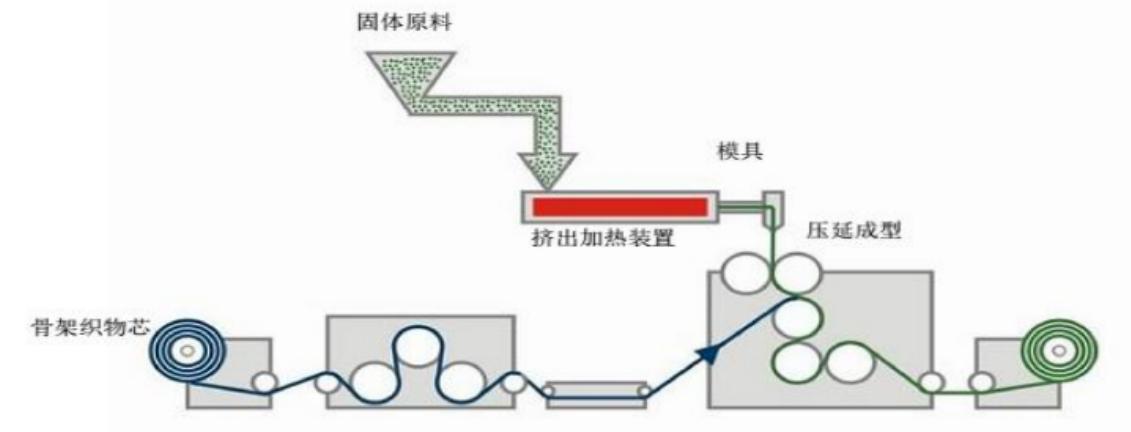

1: Extrusion calendering process

The TPU transparent granules is fed into the extruder according to the fixed formula process to extrude the film After the initial drying. The film is calendered and laminated with the rubberized base cloth. Conveyor belt be produced after multi-layer composite calendering and embossing process.

Extrusion calendering process is simple and the production efficiency is high.The belts made exclusively from extruded TPU offer a perfectly smooth, homogenous and non-porous surface. Excellent barrier against any infiltration of oils or liquids containing contaminants, they have strong resistance to usage, cuts and impacts.

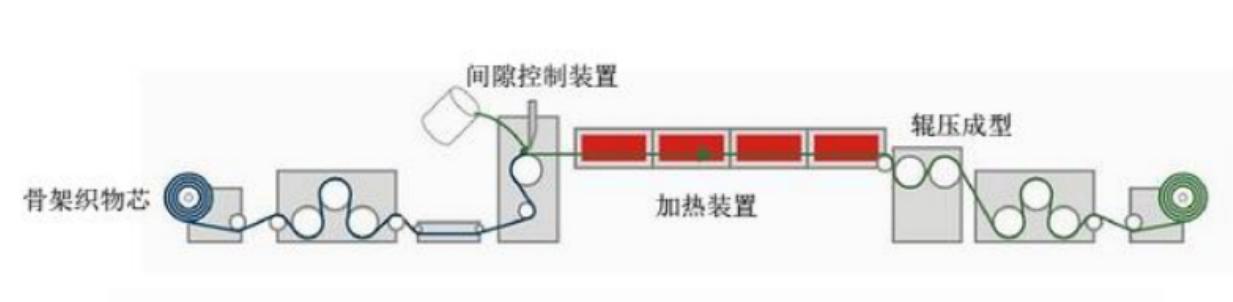

2: Coating process

TPU raw material powder is evenly coated in glue base cloth with scraper after drying and dehumidification. After infrared heating and melting, multi-roller calendering composite forming, by multi-layer composite calendering and embossing process, then the conveyor belt produced.

After color mixing, grinding and other processes, the strength of raw materials is greatly attenuated. Coating conveyor belt is easy to cause porous surface, Uneven thickness conveyor belt.

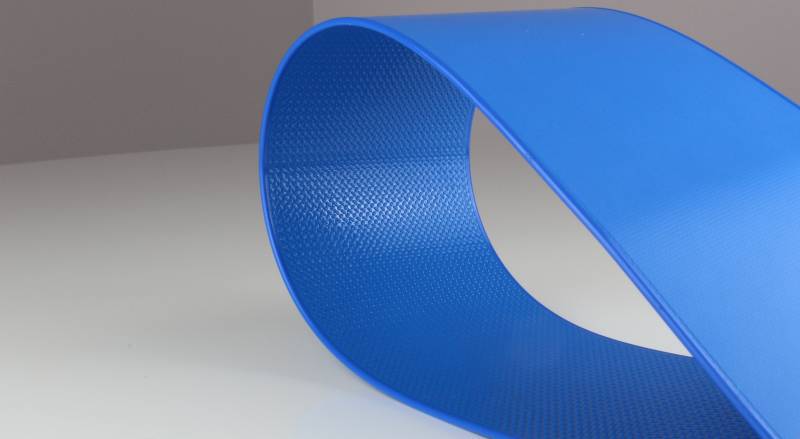

Compared with the coating process, the advantages of calendering process are: 1) avoid the change of molecular structure of raw materials which lead to poorer physical properties of the finished products. 2) After the calendering process, the thickness of the covering layer is more even and accurate 3) After the calendering process, the molecular structure of the covering layer is more compact and the product is more resistant to wear and winding 4) Avoid the processing process of raw materials from granular to powder under low temperature environment, which not only saves energy but also reduces the processing cost of raw materials.

TPU raw material powder is evenly coated in glue base cloth with scraper after drying and dehumidification. After infrared heating and melting, multi-roller calendering composite forming, by multi-layer composite calendering and embossing process, then the conveyor belt produced.

After color mixing, grinding and other processes, the strength of raw materials is greatly attenuated. Coating conveyor belt is easy to cause porous surface, Uneven thickness conveyor belt.

Compared with the coating process, the advantages of calendering process are: 1) avoid the change of molecular structure of raw materials which lead to poorer physical properties of the finished products. 2) After the calendering process, the thickness of the covering layer is more even and accurate 3) After the calendering process, the molecular structure of the covering layer is more compact and the product is more resistant to wear and winding 4) Avoid the processing process of raw materials from granular to powder under low temperature environment, which not only saves energy but also reduces the processing cost of raw materials